Established as a Proprietor firm in the year 2024, we “Jain Shots Industries” are a leading Manufacturer And Trader of a wide range of Cut Wire Shots,Riot Helmets,Sandblast Guns, etc. we are an ISO 9001:2015 certified manufacturer with an attitude to be the value partner for foundry, forging, automotive, aerospace, medical, wind tower, PEB, Pipe manufacturers and many such engineering and manufacturing sectors.

We have set up a state of the art manufacturing facility in the year 2024 to manufacture cut wire shots made from carbon steel, stainless steel, copper, aluminum and zinc wires in all shapes and sizes. We offer cut wire shots conforming to SAE J441, VDFI 8001 and IS 5873 quality standards. We cherish our relationship with more than 500 clients in India and overseas owing to consistent quality, reliability, competitive cost structure and technical support. We have a young and dynamic team continuously working to achieve highest level of customer satisfaction.

Shots manufactured from zinc-coated steel wire are known as zinc steel cut wire shots. They are used for metal surface preparation, cleaning, and deburring in industrial applications.

Copper steel cut wire shots are small metal pellets made from copper-coated steel wire. They may be accelerated at high speeds in shot blasting equipment to remove rust.

Small metal pellets known as stainless steel cut wire shots are produced from stainless steel wire. They are employed in industrial settings to polish.

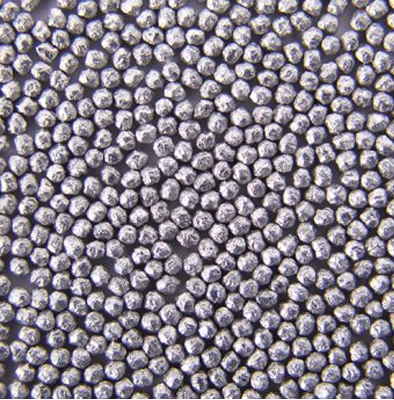

Cut Wire Shot is manufactured using high quality wire which is cut to a length about equal to its diameter. Cut wire shots can be made of carbon steel, stainless steel, aluminum, zinc, copper and other metal alloy wires. Our cut wire shots conform to SAE J441, VDFI 8001 and AMS 2431. We offer various shapes of cut wire shots:

CW – AS CUT:

These particles have sharp edges. As-Cut media is an effective cleaning abrasive but not useful for shot peening application.

CCW – SINGLE CONDITIONED (G1):

Sharp edges are removed by a process called ‘conditioning’. Conditioned cut wire shots are used for shot peening application.

DCCW – DOUBLE CONDITIONED (G2):

Another round of conditioning is done to achieve a spherical shape.

SCCW – SPHERICALLY CONDITIONED (G3):

This media is perfectly spherical in shape and it is used in aerospace and medical applications.

Due to its superior micro structure with virtually no defects (blow holes, pin tails, porosity, cracks), durability of our cut wire shots is higher than any other media.

Our cut wire shots are consistent in size, shape, hardness and density.

Our cut wire shots tend to reduce in size on use rather than fracture into smaller uneven particles which may damage components.

Our cut wire shots are durable and do not fracture, resulting in lower dust generation.

Due to consistent size, shape and hardness of our media, shot blasting cycle time reduces considerably. Eventually, saving time and money.

Cut Wire Shots have low carbon content so Iron Oxide residue on components is minimal resulting in much better and cleaner surface.

Cut wire shots are very consistent in shape, hardness, chemistry and micro structure. Right from sourcing wires, to cutting, sieving, conditioning and packing, rigorous quality checks are followed to achieve consistency in quality.

| Properties | Cast Steel Shots | Cut Wire Shots |

|---|---|---|

| Raw Material | Raw material is MS scrap | Raw material is prime quality wires |

| Technology | By nature, casting process tends to have irregularities in shape, size, hardness and micro structure, resulting in blow holes, pin tails and porosity in final product. | Each particle is cut to a length equal to its diameter. Hardness is achieved by drawing wires to the desired diameter. Result is perfectly sized granules with very narrow hardness range. |

| Hardness | Range is very big (400-500 HV) | Many options in hardness and range is very narrow. 350-400, 400-450, 450-500, 500-560, 560-630, 610-670, 660-730 HV |

| Dust Generation | Very high due to blow holes and poor micro structure | Extremely low due to superior chemistry and micro structure |

| Micro Structure | Tempered Martensite | Pearlite |

| Performance Consistency | Low | Very high |

| Blasting cycle time | High | Lower by 15-20% compared to cast shots |

| Abrasive consumption | High | Lower by 40-60% |

| Types of shots (Flexibility of raw material) | Cast steel shots and Cast stainless steel shots | Low Carbon Steel, Carbon Steel Cut Wire Shots, Stainless Steel Cut Wire Shots (SUS304, SUS316, SUS430, SUS410), Copper Cut Wire Shots, Aluminum Cut Wire Shots, Zinc Cut Wire Shots, Nickel Alloy Cut Wire Shots. |

We are an ISO 9001:2015 certified manufacturer of cut wire shots. TOCO cut wire shots conforms to SAE J441, VDFI 8001 and AMS 2431.

We offer packing in 25 kgs HDPE bags or kraft paper bags, Mounted onto 1 MT jumbo bags or wooden pallets. We use standard EURO pallet design for all export consignments.

Contrary to the industry belief, machine maintenance reduces with TOCO conditioned series of cut wire shots. Due to extremely low dust generation during shot blasting, service life of machine and dust collectors improves. Minimal down time increases productivity substantially.

We stay committed to the core values of excellence and customer satisfaction and endeavor to add to the product lineup with better productivity.

Our efficiency has become the cornerstone in providing a competitive range of metal shots & abrasives media for the blasting industries.

We are capable of delivering products in bulk within the stipulated period of time to meet our client’s demands & also we packed in superior packaging material.

To meet this objective, we lay emphasis on manufacturing only quality products and delivering them on time in professional manner to fully satisfied our client.

Copper steel cut wire shots are small metal pellets made from copper-coated steel wire. They may be accelerated at high speeds in shot blasting equipment to remove rust, scale, and other undesired contaminants from metal surfaces. In order to remove burrs and other flaws, metal pieces are put in a revolving drum containing abrasive media, such as copper steel cut wire shoots. This technique is known as barrel finishing.

The cut wire shot price in India is reasonable for consumers and cost-effective given the caliber of results it provides, allowing the industry to generate a good profit while still competing in the market.