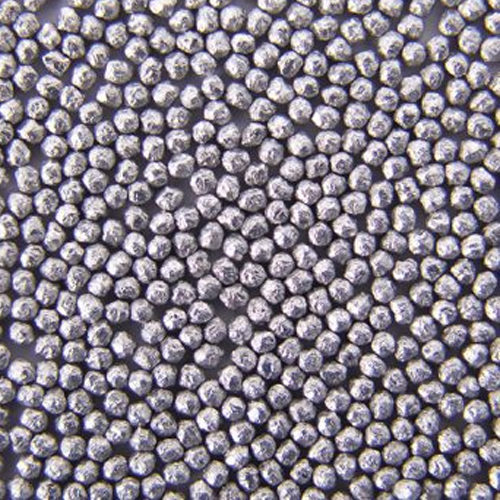

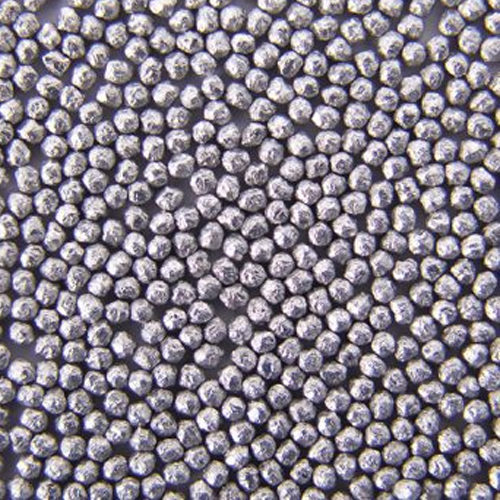

Stainless Steel Cut Wire Shots

Our Stainless Steel Cut Wire Shots are made from type AISI 316/304/202/430 Stainless Steel Wire having uniform hardness of 400 to 500 VPN or as per the requirement of our client’s needs. Our shot is certified to meet SAE J441, AMS 2431/3 and AMS 2431/4. Our shot is available in conditioned form (spherical) & As-Cut form (cylindrical). It gives you extra white finish, and dust accumulation will be NIL. Life will be approx 8-10 times higher life than Steel Shots/Grits and 4-5 times higher life than Steel Cut Wire Shots.

Our Stainless Steel Cut Wire Shots are manufactured using premium AISI 316, 304, 202, or 430 stainless steel wire, with a consistent hardness ranging from 400 to 500 VPN, or tailored to meet specific client requirements. Certified to comply with SAE J441, AMS 2431/3, and AMS 2431/4 standards, our shots are available in both conditioned (spherical) and as-cut (cylindrical) forms. These shots provide an exceptionally wide, uniform finish with zero dust accumulation.

With a lifespan approximately 8-10 times longer than steel shots or grits, and 4-5 times longer than steel cut wire shots, our stainless steel shots offer superior durability. They are ideal for critical applications where ferrous contamination would be detrimental, such as blasting stainless steel, titanium, aluminum, or other non-ferrous materials, ensuring a clean and contaminant-free surface.

Steel Wire Shots are made from high-quality carbon steel wire, typically exhibiting a hardness between 30-45 HRC. They are available in spherical shapes with diameters ranging from 0.2 mm to 2.5 mm and have a density of approximately 7.85 g/cm³. These shots are designed for shot peening, surface cleaning, and enhancing the fatigue resistance of components, making them suitable for both ferrous and non-ferrous materials. Packaged in bulk bags or drums, Steel Wire Shots comply with industry standards like SAE J441 and ISO 11124, ensuring long-lasting performance with good wear resistance.

Specification

Sizes we manufacture: 0.3mm to 2.5mm

Average Vickers Hardness: 400–500 VPN or as required by the customer

Minimum density: 7.8g/cm³

Surface finishing: Extreme whiter finish

Packaging: 25 Kgs Alkathene lined double gunny bags

Standards: SAE J441, AMS 2431/3 and AMS 2431/4

high quality stainless steel cut wire shots manufactured in delhi for shot blasting, peening, cleaning, and surface preparation. suitable for automotive, aerospace, foundry, forging, and engineering industries. consistent hardness, precise size, long life, low dust generation, and reliable performance for industrial applications.

trusted manufacture of stainless steel cut wire shots in new delhi offering uniform shape, controlled hardness, and excellent durability. ideal for metal cleaning, polishing, deburring, and shot peening applications across automotive, medical, aerospace, and heavy engineering sectors with assured quality standards.

leading stainless steel cut wire shots manufacture in ghaziabad delivering high strength, low fracture media for blasting and peening. designed for consistent results, reduced cycle time, minimal dust, and cleaner surface finish for industrial components used in multiple engineering sectors.

precision stainless steel cut wire shots manufacture in noida for efficient surface treatment solutions. widely used in shot blasting and peening machines for rust removal, cleaning, and finishing. ensures uniform size, superior durability, and long operational life for cost-effective production.

reliable stainless steel cut wire shots manufacture in uttar pradesh serving diverse industries. produced under strict quality control for accurate dimensions, consistent hardness, and excellent wear resistance. suitable for heavy-duty blasting, peening, and surface preparation applications across india.

advanced stainless steel cut wire shots manufacture in haryana for high performance blasting media. offers clean surface finish, reduced dust generation, and long service life. ideal for automotive, forging, aerospace, and fabrication industries requiring dependable and uniform abrasive solutions.

industrial grade stainless steel cut wire shots manufacture in gurugram for precision surface finishing. engineered to provide consistent peening intensity, improved fatigue strength, and minimal breakdown. trusted choice for manufacturers seeking reliable and cost-effective blasting media solutions.

premium stainless steel cut wire shots manufacture in faridabad supplying durable and uniform blasting media. ensures excellent resistance to fracture, stable performance, and cleaner working environment. widely used for metal cleaning, deburring, and polishing in engineering industries.

quality stainless steel cut wire shots manufacture in rajasthan for efficient shot blasting and peening operations. manufactured for high density, consistent size, and superior durability. supports industries demanding long-lasting abrasive media with reliable and repeatable surface finishing results.

trusted stainless steel cut wire shots manufacture in punjab providing precision engineered blasting media. suitable for heavy industrial applications requiring uniform hardness and low dust generation. enhances productivity, improves surface quality, and reduces operational costs for manufacturers.

specialized stainless steel cut wire shots manufacture in uttarakhand delivering high purity and performance media. ideal for aerospace, medical, and automotive components where consistent surface finish and controlled peening results are critical for product reliability.

leading stainless steel cut wire shots manufacture in north india serving multiple industrial sectors. designed for superior wear resistance, uniform shape, and long service life. perfect for shot blasting, peening, and surface preparation across diverse manufacturing environments.

professional stainless steel cut wire shots manufacture near delhi ncr offering reliable abrasive solutions. ensures stable performance, reduced media consumption, and clean finishing. widely preferred by industries for precision blasting, polishing, and metal surface treatment needs.

pan india stainless steel cut wire shots manufacture supplying consistent and durable blasting media. produced to meet industrial standards for quality, hardness, and size accuracy. suitable for various applications including peening, cleaning, and surface finishing across india.

expert stainless steel cut wire shots manufacture delivering high efficiency abrasive media. developed for demanding industrial use with low breakdown rate and superior consistency. helps achieve uniform surface finish, improved productivity, and long-term cost savings.